Intermediate Sensor Inspection [FS5A-EL]

INTERMEDIATE SENSOR INSPECTION [FS5A-EL]1. Connect the WDS or equivalent, drive the vehicle, and verify the input value of the ISS PID.

^ If the input value is 0 rpm, perform the "Power Supply Voltage Inspection", "Open Circuit Inspection", or "Short Circuit Inspection".

^ If the input value is other than 0 rpm, perform the "Visual Inspection" or "Wave Profile Inspection".

Visual Inspection

1. Remove the intermediate sensor.

2. Make sure that the sensor is free of any metallic shavings or particles.

^ If any are found on the sensor, clean them off.

3. Install the intermediate sensor.

Wave profile Inspection

1. Remove the TCM.

2. Connect WDS or equivalent to DLC connector.

3. Connect oscilloscope test leads to the following TCM connector terminals. lead: TCM terminal 2L lead: TCM terminal 1 P

4. Start the engine.

5. Monitor VSS PID.

6. Inspect wave profile.

^ TCM terminal: 2L (+) - 1P (-)

^ Oscilloscope setting: 1 V/DIV (Y), 2.5 ms/DIV (X), DC range

^ Vehicle condition: drive the vehicle with 32 km/h (20 mph)

- If wave profile or voltage are out of specifications, carry out the "Open Circuit Inspection" or "Short Circuit Inspection"

Power Supply Voltage Inspection

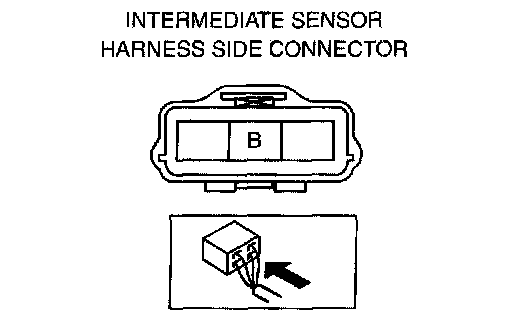

1. Disconnect the intermediate sensor connector.

2. Turn the ignition switch to ON.

3. Measure voltage at intermediate sensor connector terminal B (wiring harness side).

Intermediate sensor voltage 4.5 - 5.5 Volts

^ If voltage is okay, go to Open Circuit Inspection and Short Circuit Inspection.

^ If voltage is wrong, repair wiring harness between intermediate sensor and TCM.

Open Circuit Inspection

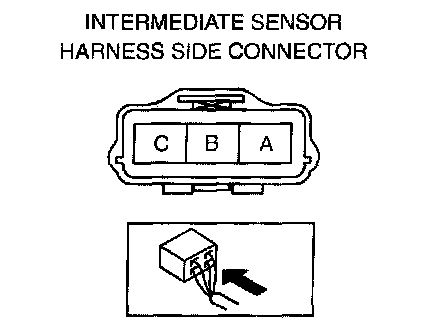

1. Inspect the following circuit for open.

^ Power circuit (intermediate sensor connector terminal A to main relay terminal D)

^ Ground circuit (intermediate sensor connector terminal C to GND)

^ If an open circuit or short circuit is found, repair the malfunctioning wiring harness.

^ If there are no open or short circuits, perform the sensor rotor inspection.

Short Circuit Inspection

1. Inspect the following circuit for short.

^ Power circuit (intermediate sensor connector terminal A to main relay terminal D)

^ If an open circuit or short circuit is found, repair the malfunctioning wiring harness.

^ If there are no open or short circuits, perform the sensor rotor inspection.

Secondary Gear Inspection

1. Remove the intermediate sensor.

2. Shift the selector lever to N position.

3. Inspect secondary gear surface via intermediate sensor installation hole while rotating the front tire manually.

1) Is secondary gear free of damage and cracks?

2) Is secondary gear free of any metallic shavings or particles?

^ If secondary gear is okay, replace the intermediate sensor.

^ If there is a problem, clean or replace the secondary gear.