Leak Detection Pump: Testing and Inspection

EVAPORATIVE EMISSION (EVAP) SYSTEM LEAK DETECTION PUMP INSPECTIONAirflow Inspection

NOTE: Perform the following test only when directed.

1. Disconnect the negative battery cable.

2. Remove the EVAP system leak detection pump.

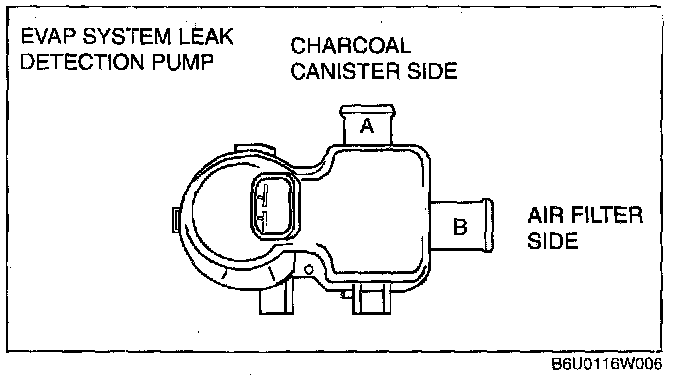

3. Blow air into port A and verify that there is airflow from port B.

- If not as specified, replace the EVAP system leak detection pump.

4. Blow air into port B and verify that there is airflow from port A.

- If not as specified, replace the EVAP system leak detection pump.

- If as specified, perform the following "Resistance Inspection".

Resistance Inspection

NOTE: Perform the following procedure only when directed.

1. Disconnect the negative battery cable.

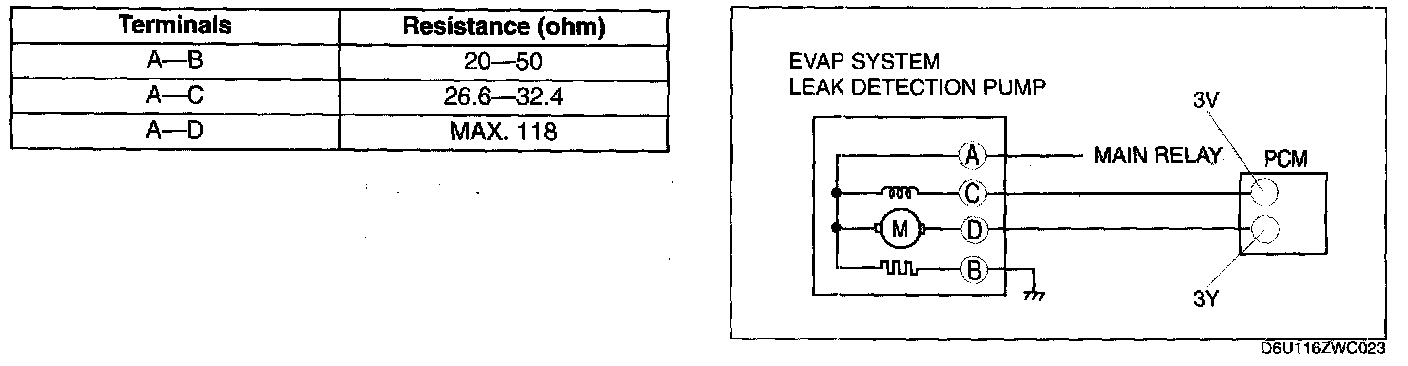

2. Inspect resistance of the EVAP system leak detection pump.

- If not as specified, replace the EVAP system leak detection pump.

- If as specified, carry out the "Circuit Open/Short Inspection".

Circuit Open/Short Inspection

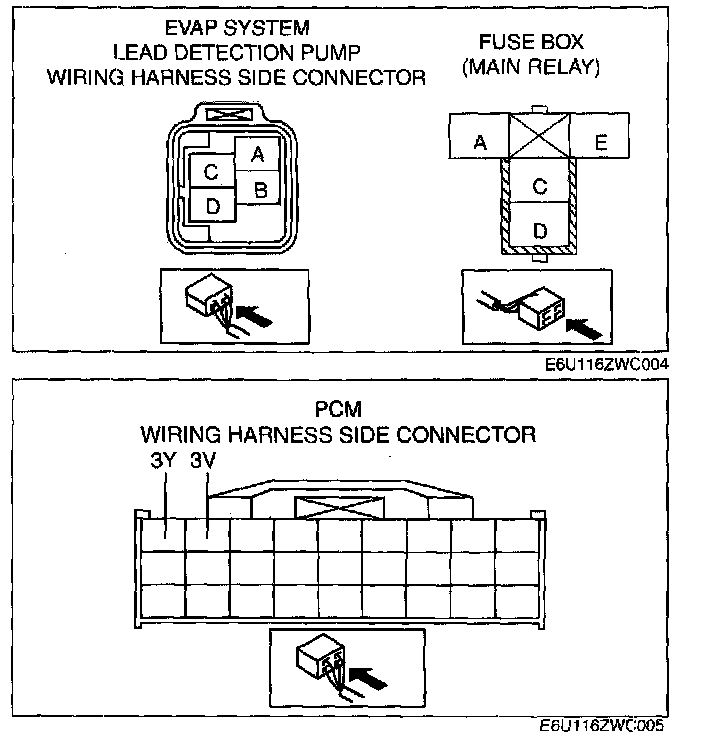

1. Disconnect the PCM connector.

2. Inspect the following wiring harnesses for an open or short circuit (continuity check).

Open circuit

- If there is no continuity, there is an open circuit. Repair or replace the wiring harness.

- EVAP system leak detection pump terminal C and PCM terminal 3V

- EVAP system leak detection pump terminal D and PCM terminal 3Y

- EVAP system leak detection pump terminal A and main relay terminal C

- EVAP system leak detection pump terminal B and the body Ground.

Short circuit

- If there is continuity, there is a short circuit. Repair or replace the wiring harness.

- EVAP system leak detection pump terminal C and power supply

- EVAP system leak detection pump terminal D and power supply

- EVAP system leak detection pump terminal A and the body Ground

- EVAP system leak detection pump terminal B and power supply