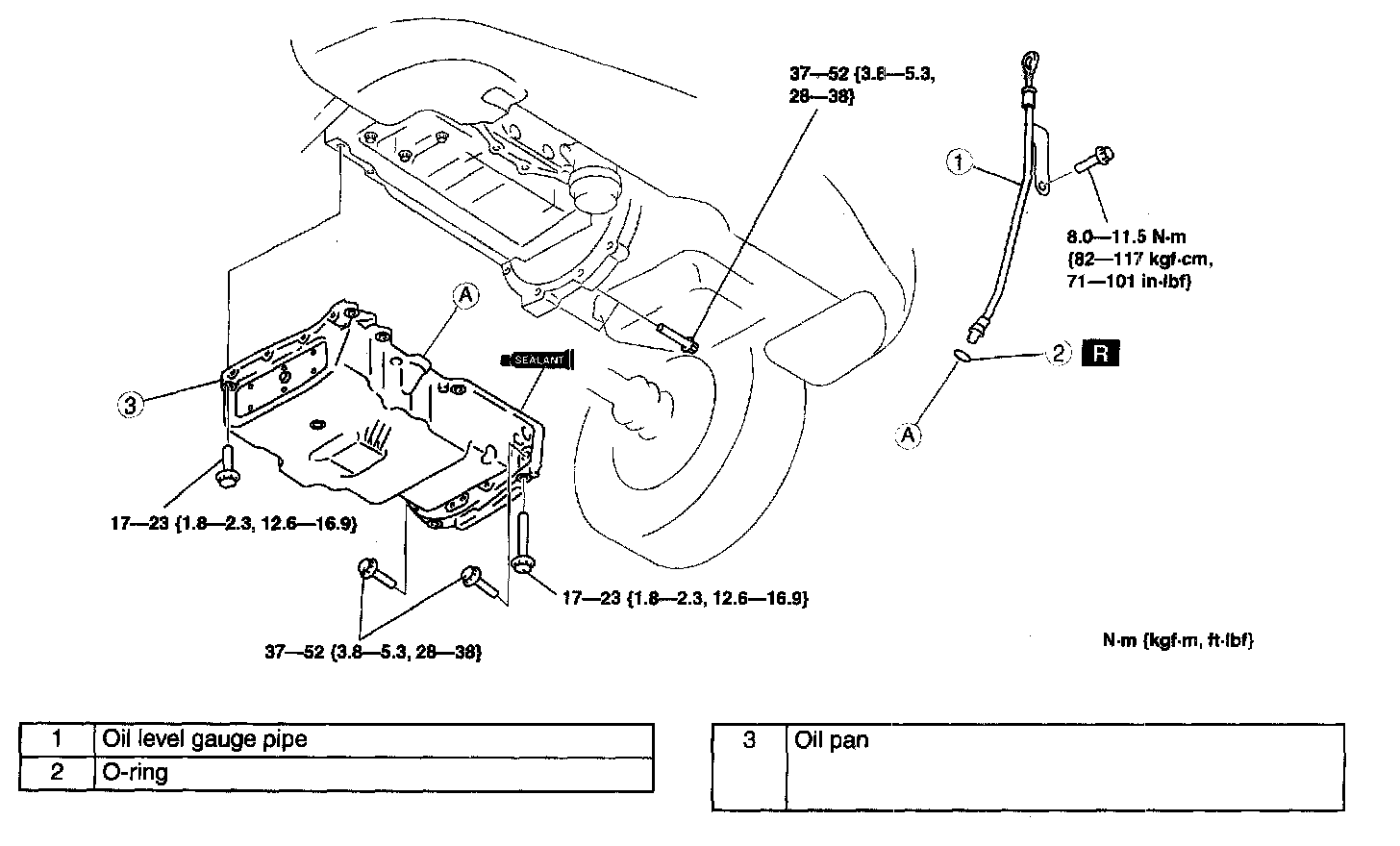

Oil Pan: Service and Repair

OIL PAN REMOVAL/INSTALLATION [L-3 WITH TC]Warning:

- Hot engines and engine oil can cause severe burns. Turn off the engine and wait until it and the engine oil have cooled.

- A vehicle that is lifted but not securely supported on safety stands is dangerous. It can slip or fall, causing death or serious injury. Never work around or under a lifted vehicle if it is not securely supported on safety stands.

- Continuous exposure to USED engine oil has caused skin cancer in laboratory mice. Protect your skin by washing with soap and water immediately after working with engine oil.

1. Disconnect the negative battery cable.

2. Remove the under cover.

3. Drain the engine oil.

4. Remove the engine front cover.

5. Remove in the order indicated in the table.

6. Install in the reverse order of removal.

7. Refill with the specified type and amount of the engine oil,

8. Start the engine and confirm that there is no oil leakage.

- If there is oil leakage, repair or replace the applicable part.

9. Inspect the oil level.

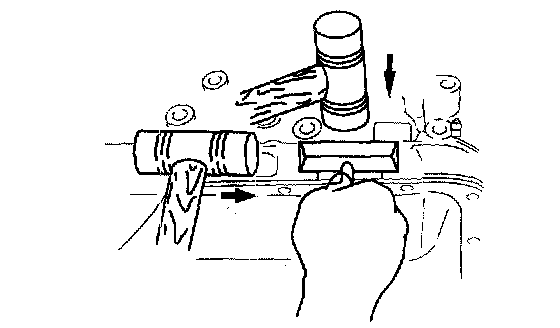

Oil Pan Removal Note

1. Remove the oil pan using the separator tool.

Oil Pan Installation Note

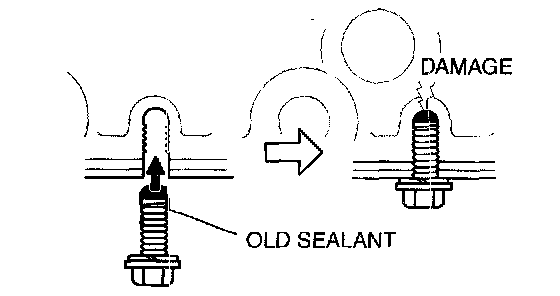

Caution:

- Apply the silicon sealant in a single, unbroken line around the whole perimeter. Using bolts with the old seal adhering could cause cracks in the housing.

1. Completely clean and remove any oil, dirt, sealant or other foreign material that may be adhering to the housing and oil pan.

2. When reusing the oil pan installation bolts, clean any old sealant from the bolts.

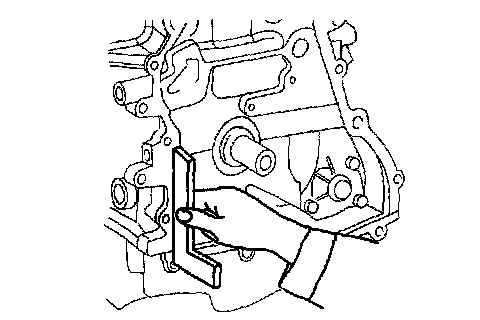

3. Use a square ruler to align the oil pan and the cylinder block junction side on the engine front cover side.

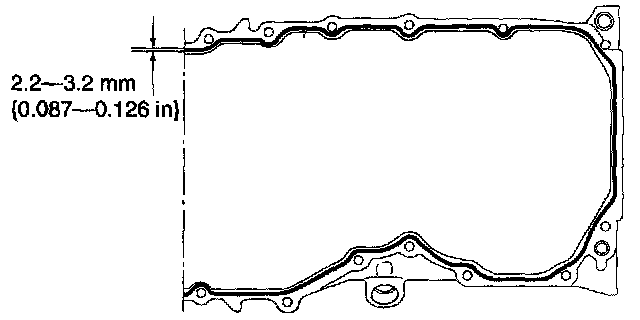

4. Apply silicone sealant to the oil pan along the inside of the bolt holes as shown in the figure.

Thickness 2.2 - 3.2 mm (0.087 - 0.126 inch)

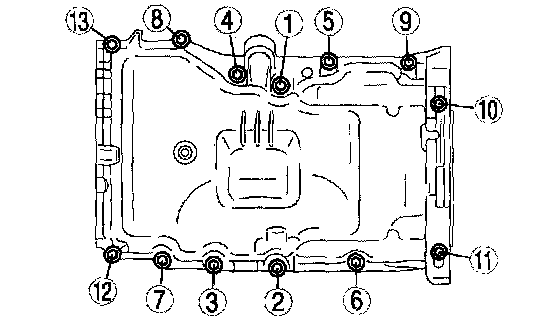

5. Tighten the bolts in the order shown in the figure.

Tightening torque 17 - 23 Nm (1.8 - 2.3 kgf-m, 12.6 - 16.9 ft. lbs.)

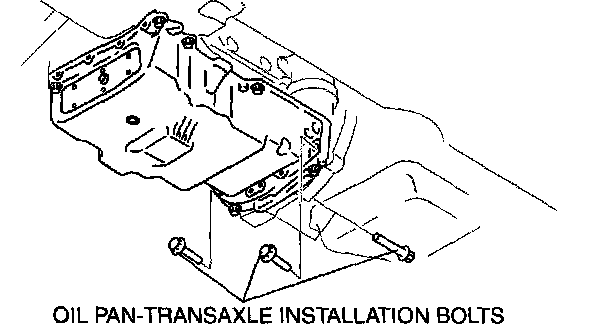

6. Tighten the oil pan-transaxle installation bolts.

Tightening torque 37 - 52 Nm (3.8 - 5.3 kgf-m, 28 - 38 ft. lbs.)