Camshaft Gear/Sprocket: Testing and Inspection

VARIABLE VALVE TIMING ACTUATOR INSPECTION [L3 WITH TC]Caution:

- Due to the precision interior construction of the variable valve timing actuator, it cannot be disassembled.

1. Disconnect the negative battery cable.

2. Remove the charge air cooler.

3. Remove the ignition coils.

4. Remove the spark plugs.

5. Disconnect the OCV connectors.

6. Disconnect the CMP sensor connector.

7. Disconnect the P/S oil pump connector.

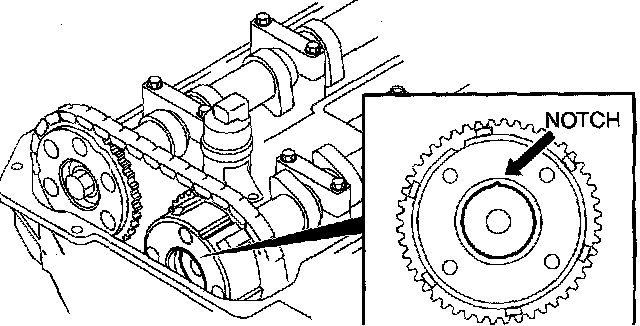

8. Remove the ventilation hose.

9. Remove cylinder head cover.

10. Verify that the groove of the rotor and notch of the cover on the variable valve timing actuator are aligned and fitted.

- If they are not aligned, rotate the crankshaft in the direction of engine rotation two times and verify that they are aligned.

- If they will not align, replace the variable valve timing actuator.

- If under any condition, the variable valve timing actuator always makes a hitting noise directly after the camshaft exceeds maximum lift while rotating the crankshaft two times in the direction of engine rotation, replace the variable valve timing actuator as it has not been fixed.

11. Install the cylinder head cover.

12. Install the ventilation hose.

13. Connect the P/S oil pump connector.

14. Connect the CMP sensor connector.

15. Connect the OCV connector.

16. Install the spark plugs.

17. Install the ignition coils.

18. Install the charge air cooler.

19. Connect the negative battery cable.