Valve Clearance Inspection

VALVE CLEARANCE INSPECTION1. Turn the crankshaft clockwise so that the No.1 piston is at TDC of the compression stroke.

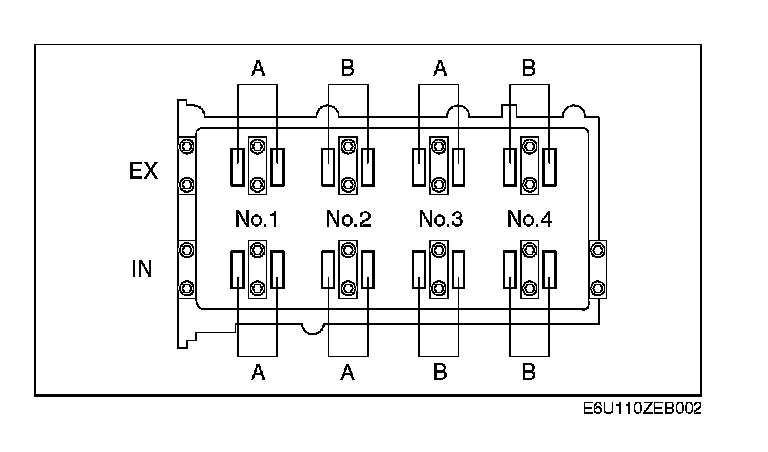

2. Measure the valve clearance at A in the figure.

- If it is not within the specification, replace the tappet and adjust the valve clearance to the standard clearance.

Standard valve clearance [when cold]

IN: 0.22-0.28 mm (0.0087-0.0110 in)

EX: 0.27-0.33 mm (0.0106-0.0130 in)

Note

- When replacing the tappet, select the tappet according to the measured value and note down the measured value.

3. Rotate the crankshaft clockwise 360° so that the No.4 piston is at the TDC of the compression stroke.

4. Measure the valve clearance at B in the figure.

- If it is not within the specification, replace the tappet and adjust the valve clearance to the standard clearance.

Standard valve clearance [when cold]

IN: 0.22-0.28 mm (0.0087-0.0110 in)

EX: 0.27-0.33 mm (0.0106-0.0130 in)

Note

- When replacing the tappet, select the tappet according to the measured value and note down the measured value.