Fuel Gauge Sender: Service and Repair

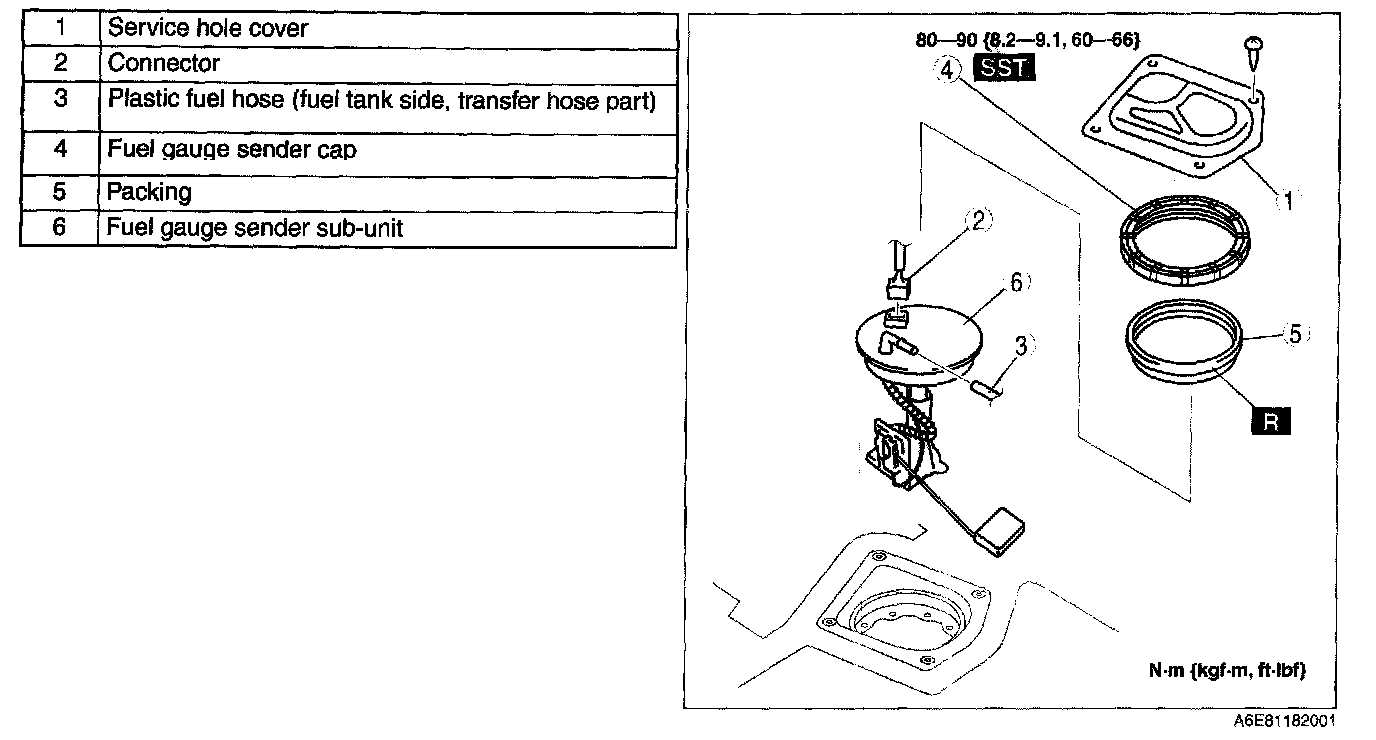

FUEL GAUGE SENDER UNIT REMOVAL/INSTALLATION [AWD]Fuel Gauge Sender Unit

1. Remove the fuel gauge sender unit.

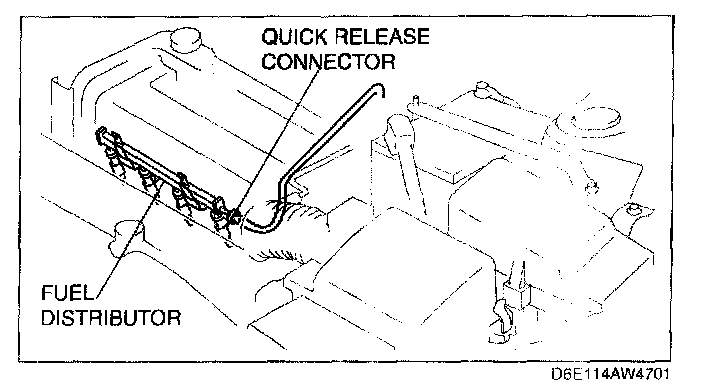

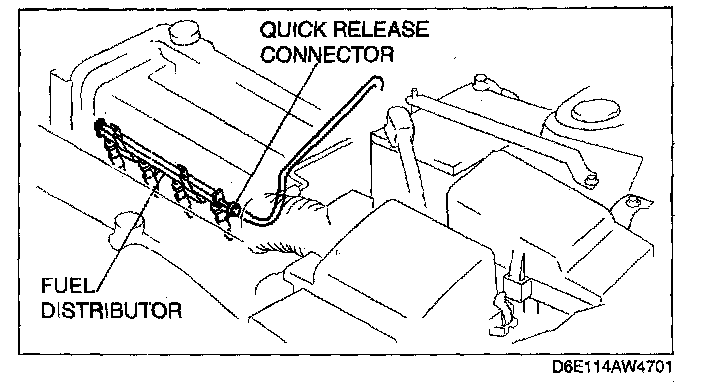

2. Install in the reverse order of removal.

Fuel Gauge Sender Sub-Unit

WARNING:

- Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete the "Fuel Line Safety Procedure".

- A person charged with static electricity could cause a fire or explosion, resulting in death or serious injury. Before draining fuel, make sure to discharge static electricity by touching a vehicle.

CAUTION:

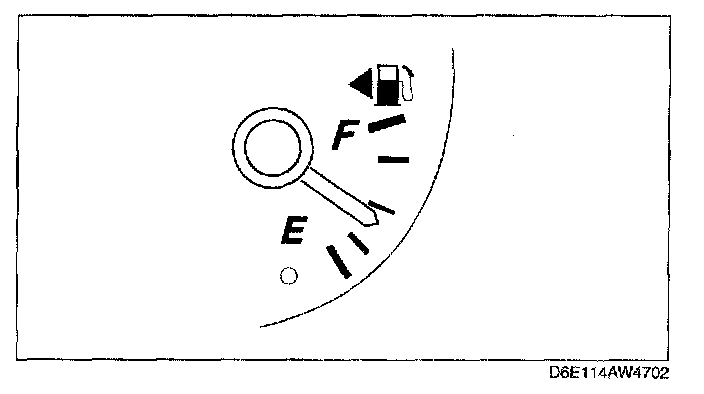

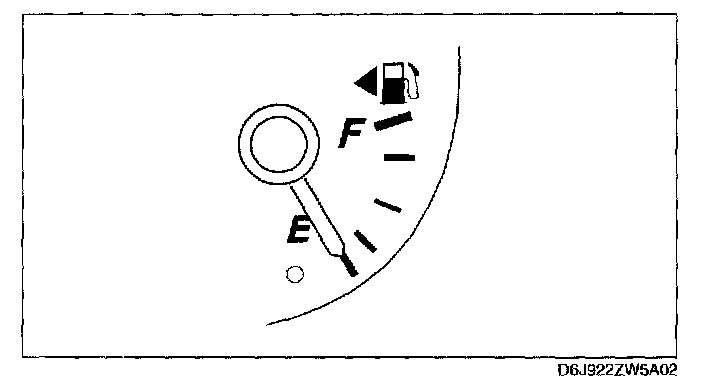

Because the fuel tank is constructed such that the fuel level is higher than the installation surface of the fuel pump, fuel leakage could occur. If the fuel gauge indicates a fuel level of half or more, perform the following Steps 1-14 to drain the fuel.

Disconnecting/connecting the quick release connector without cleaning it may possibly cause damage to the fuel pipe and quick release connector. Always clean the quick release connector joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is free of foreign material.

1. Complete the "BEFORE REPAIR PROCEDURE.

2. Remove the plug hole plate.

3. Disconnect the quick release connector connected to the fuel distributor.

4. Connect a long hose to the disconnected quick release connector and drain the fuel into a container used for collecting gasoline.

5. Start the fuel pump using the following procedure.

Using WDS or equivalent

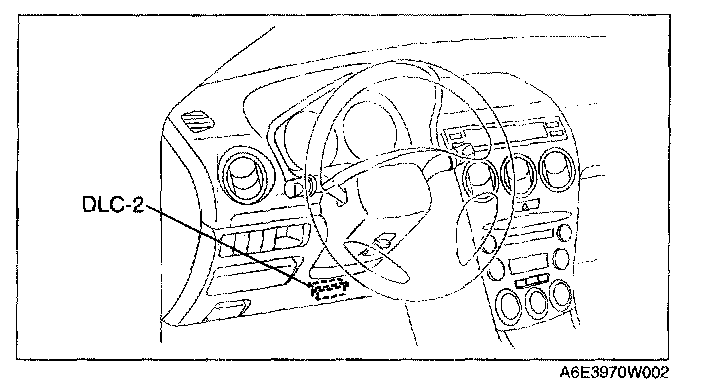

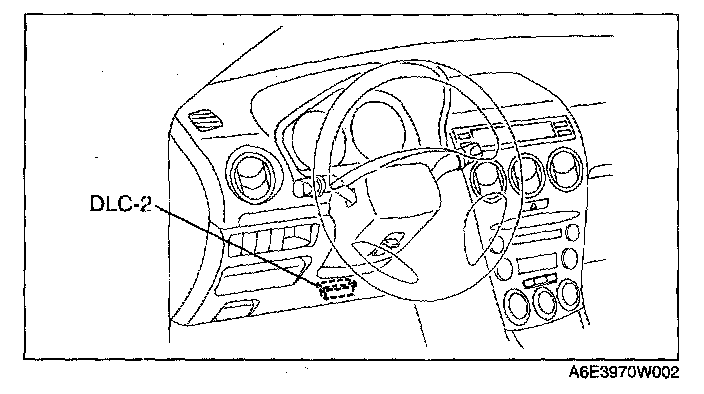

1. Connect the WDS or equivalent to the DLC-2.

2. Using the simulation function "FP", start the fuel pump.

Without using WDS or equivalent

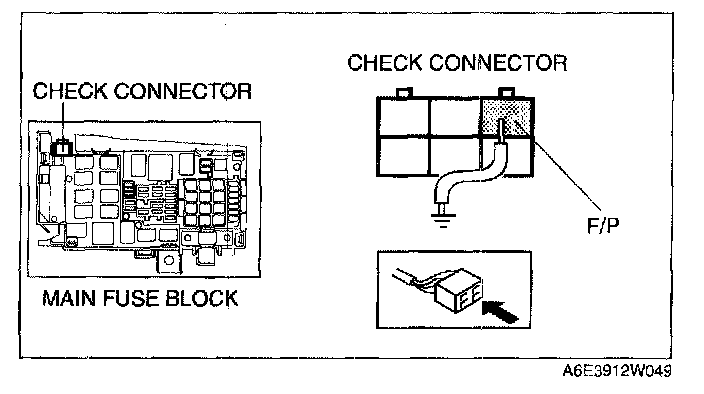

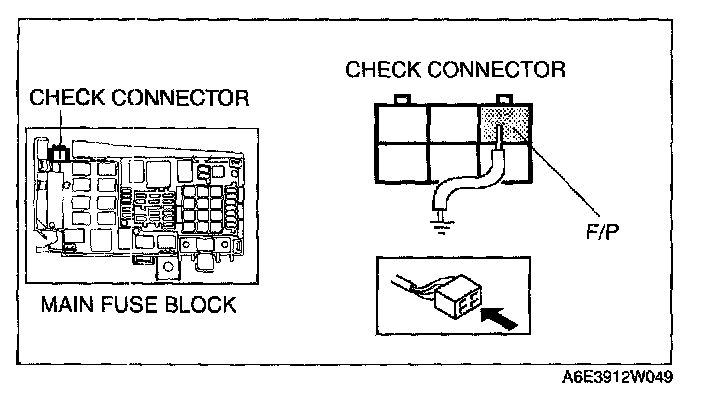

1. Short the check connector terminal F/P to body GND using a jumper wire.

2. Turn the ignition switch to ON position to operate the fuel pump.

CAUTION: The fuel pump could be damaged if it is operated (fuel pump idling) while there is no fuel in the fuel tank. Verify the amount of fuel being discharged from the hose and stop operation of the fuel pump when essentially no fuel is being discharged.

NOTE: If the fuel tank is full, drain approx. 40 L {10.6 US gal, 8.8 Imp gal} of fuel until the fuel gauge indicates approx. 3/8 of a tank.

6. Stop operation of the fuel pump when essentially no fuel is being discharged.

7. Reconnect the quick release connector to the fuel distributor.

8. Start the engine and idle it for 15 min (to transfer fuel from the sub-tank to the main tank).

9. Stop the engine.

10. Complete the "BEFORE REPAIR PROCEDURE".

11. Remove the plug hole plate.

12. Disconnect the quick release connector connected to the fuel distributor.

13. Connect a long hose to the disconnected quick release connector and drain the fuel into a container used for collecting gasoline.

14. Start the fuel pump using the following procedure.

Using WDS or equivalent

Connect the WDS or equivalent to the DLC-2. Using the simulation function "FP", start the fuel pump.

Without using WDS or equivalent

1. Short the check connector terminal F/P to body GND using a jumper wire.

2. Turn the ignition switch to ON position to operate the fuel pump.

CAUTION: The fuel pump could be damaged if it is operated (fuel pump idling) while there is no fuel in the fuel tank. Verify the amount of fuel being discharged from the hose and stop operation of the fuel pump when essentially no fuel is being discharged.

NOTE: If the fuel tank is full, drain approx. 55 L (15 US gal, 12 Imp gal) of fuel until the fuel gauge indicates E position.

15. Stop operation of the fuel pump when essentially no fuel is being discharged.

16. Disconnect the negative battery cable.

17. Complete the following in order to the work area.

1. Loosen the bolt of the fuel tank strap.

2. Lower the fuel tank to a position where the SST can be attached from the service hole cover.

18. Remove the rear seat cushion.

19. Remove in the order indicated in the above table.

20. Install in the reverse order of removal.

21. Complete the "AFTER REPAIR PROCEDURE".

22. Complete the "Fuel leak inspection after fuel gauge sender sub-unit installation."

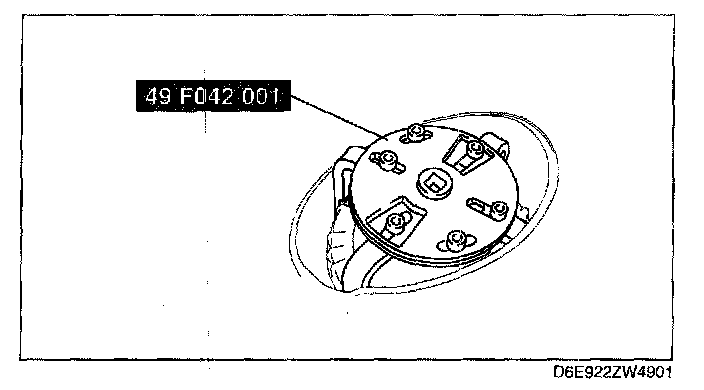

Fuel gauge sender cap removal note

1. Using the SST, remove the fuel gauge sender cap.

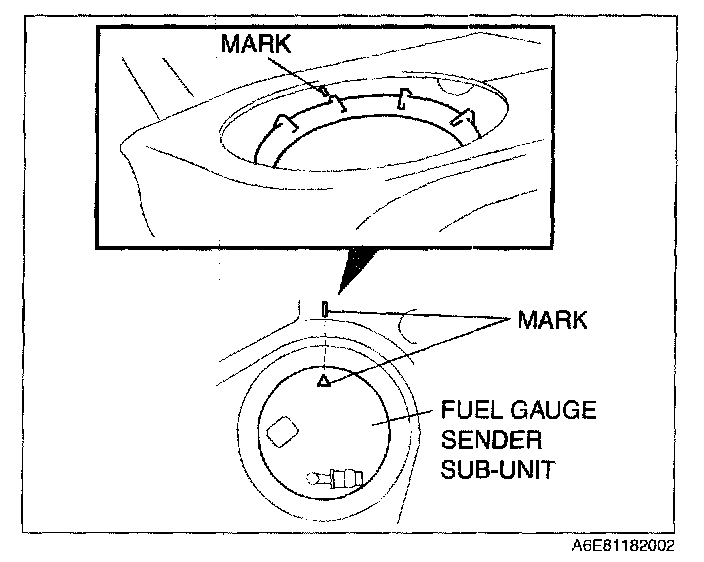

Fuel Gauge Sender Cap Installation Note

1. Verify that the fuel tank mark is aligned with the fuel gauge sender sub-unit mark as shown.

2. Using the SST, tighten the fuel gauge sender cap without shifting the mark.

Tightening torque: 80-90 N-m (8.2-9.1 kgf-m, 60-66 ft- lbf)

Fuel leak inspection after fuel gauge sender sub-unit installation

1. Drive the vehicle.

2. Perform a quick start and a hard brake 5-6 times.

3. Stop the vehicle.

4. Verify that there is no fuel leakage near the fuel pump unit in the vehicle interior.