High Pressure Fuel Pump Removal and Installation

HIGH PRESSURE FUEL PUMP REMOVAL/INSTALLATIONCAUTION:

- Do not disassemble the high pressure fuel pump.

- Do not scratch or damage the fuel sealing surface of the high and low fuel ports.

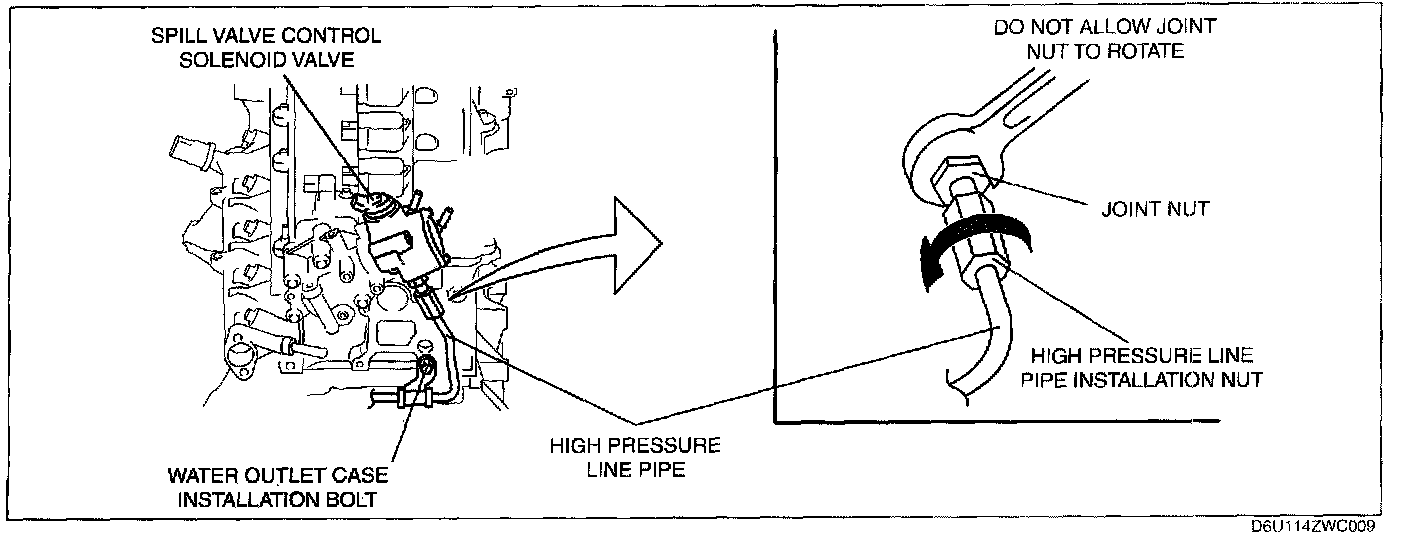

- When removing the high pressure fuel pipe, secure the joint (pump side) so that it dose not rotate, and loosen the screw (pipe side).

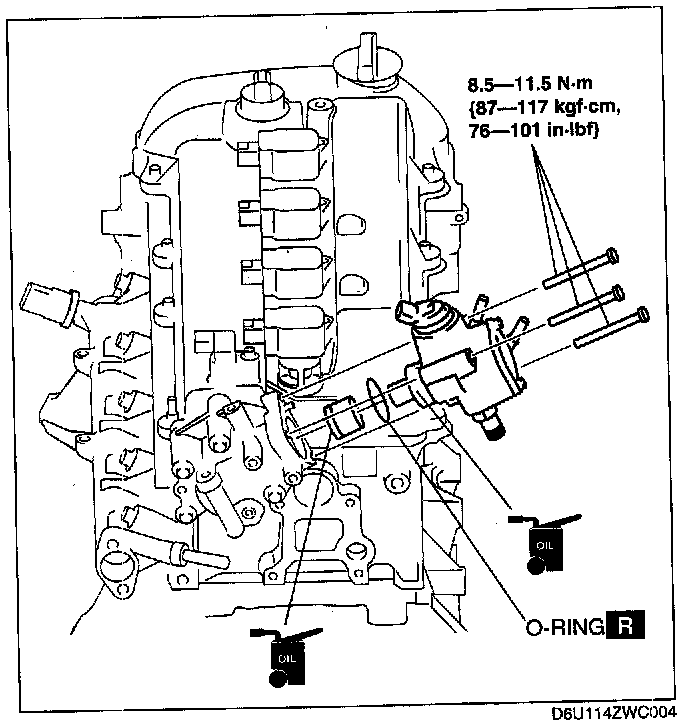

NOTE: If the high pressure fuel pump is removed, replace the O-ring with a new one.

1. Complete the "BEFORE REPAIR PROCEDURE".

2. Disconnect the negative battery cable.

3. Remove the charge air cooler cover.

4. Disconnect the spill valve control solenoid valve connector.

5. Disconnect the quick release connector on the high pressure fuel pump.

6. Remove the battery and battery tray.

WARNING: If the high pressure fuel pump joint nut is loosened, fuel leakage may occur resulting in death or serious injury, or damage to the equipment or the vehicle. Fuel can also irritate the skin and eyes. When removing the high pressure line pipe, always tighten the high pressure line pipe installation nut while fixing the high pressure fuel pump joint nut with a wrench. If the high pressure fuel pump joint nut has rotated, replace the high pressure fuel pump with a new one.

7. Disconnect the high pressure line Dice of the high pressure fuel Dump.

1. Fix the joint nut with a wrench on the high pressure fuel pump side as shown in the figure.

2. Loosen the high pressure line pipe installation nut.

8. Drain engine coolant. (See ENGINE COOLANT REPLACEMENT.)

9. Loosen the water outlet case installation bolts securing the high pressure line Dice.

10. Remove the high pressure fuel pump.

11. Remove the high pressure fuel pump cover.

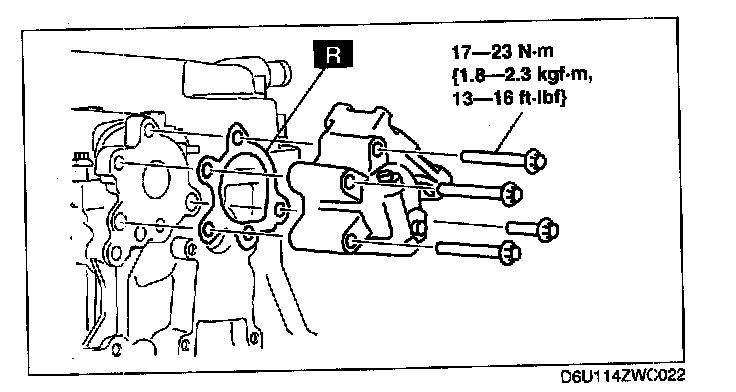

12. Tighten the bolts on the high pressure fuel pump cover.

Tightening torque: 17-23 N-m {1.8-2.3 kgf.m, 13-16 ft.lbf}

CAUTION: If the high pressure fuel pump installation bolts are tightened with the high pressure fuel pump tilted, the high pressure fuel pump may not operate correctly. Tighten the high pressure fuel pump installation bolts in a few passes with equal torque.

13. Tighten the bolts on the high pressure fuel pump.

Tightening torque: 8.5-11.5 N.m {87-117 kgf.m, 76-101 ft.lbf}

WARNING: If the high pressure fuel pump joint nut is loosened, fuel leakage may occur resulting in death or serious injury, or damage to the equipment or the vehicle. Fuel can also irritate the skin and eyes. When installing the high pressure line pipe, always tighten the high pressure line pipe installation nut while fixing the high pressure fuel pump joint nut with a wrench. If the high pressure fuel pump joint nut has rotated, replace the high pressure fuel pump with a new one.

14. Assemble the high pressure line pipe.

1. Fix the joint nut with a wrench on the high pressure fuel pump side as shown in the figure.

2. Tighten the high pressure line pipe installation nut.

Tightening torque: 23.5-35.5 N.m {2.40-3.61 kgf.m, 17.4-26.1 ft.lbf}

15. Tighten the water outlet case installation bolts.

Tightening torque: 8-11.5 N.m {117 kgf.cm, 71-101 in.lbf}

16. Install the quick release connector.

Fuel Leakage Inspection After High Pressure Fuel Pump Installation

1. Verify that the high pressure fuel pump is assembled securely.

2. Drive the vehicle starting from a standstill and brake suddenly five to six times at a low speed.

3. Stop the vehicle and verify from outside the vehicle that there is no fuel leakage around the high pressure fuel pump.