Variable Induction System: Testing and Inspection

Variable Swirl System Operation Inspection1. Connect the WDS or equivalent to the DLC-2.

2. Access the ECT PID.

3. Verify that the ECT PID is below 60 degrees C {140 degrees F}.

4. Start the engine.

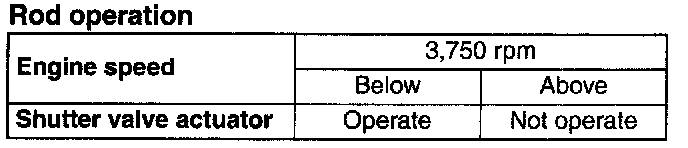

5. Inspect the rod operation under the following conditions:

If the rod operation is not specified, inspect as follows:

1. Perform the KOER self-test using the WDS or equivalent and verify that DTCs No. P2004, P2006, P2009 or P2010 are not displayed.

- If DTC No. P2004, P2006, P2009 or P2010 are displayed, perform DTC inspection. (See DTC TABLE.) Diagnostic Trouble Code Descriptions

If simulation function of WDS or equivalent is used:

1. Turn the ignition switch to the ON position. (Engine off)

2. Turn the variable swirl solenoid valve from off to on using the IMRC PID and verify that the operation sound of the solenoid valve is heard.

- If the operation sound is not heard, replace the variable swirl solenoid valve,

- If the operation sound is not heard, inspect the following:

- Vacuum hose and vacuum chamber for looseness or damage

- Shutter valve actuator.

- Check valve is stuck open or closed

- Shutter valve cannot move smoothly

If simulation function of WDS or equivalent is not used

1. Inspect variable swirl solenoid valve.

- If the variable swirl solenoid valve is not normal, replace the variable swirl solenoid valve.

- If the variable swirl solenoid valve is normal, inspect the following:

- Vacuum hose and vacuum chamber for looseness or damage

- Shutter valve actuator

- Check valve is stuck open or closed

- Shutter valve cannot move smoothly.